Get Support

+91 90045 37958

About Us

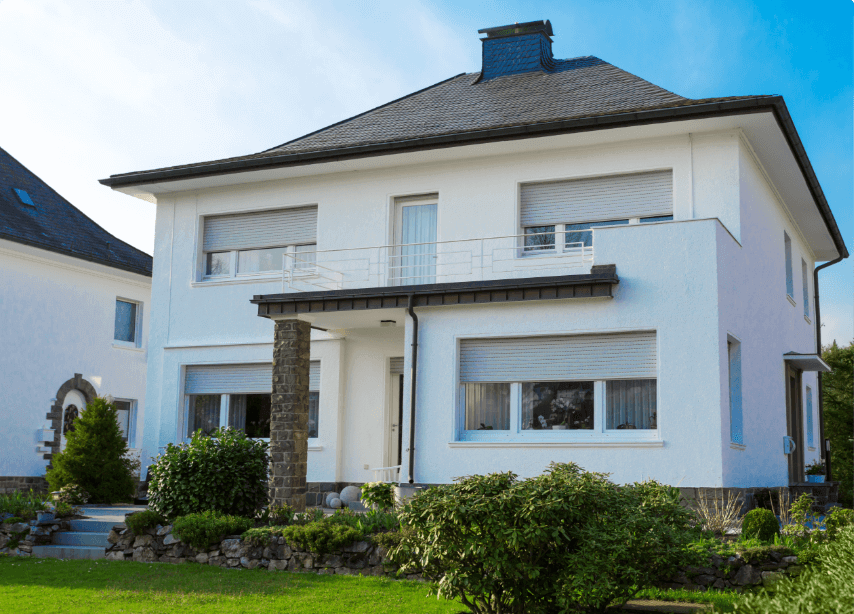

PORTABLE CABIN MANUFACTURER.

Offering a wide range of portable cabins, bunkhouses, security cabins, mobile toilets, toll booths, factory sheds, porta cabins, site offices, security guard cabins, portable buildings, etc. Our motto is to exceed customer expectations by providing the highest quality products and prompt services. We are dedicated towards developing long-term and mutually-enriching relationships with our customers by offering them exactly what they demand for. Our company is recognized worldwide as a leading manufacturer and exporter of different types of portable cabins including a durable range of Bunk House, Security Cabins, Toll Booths, Factory Shed, Porta Cabins, Site Offices, Security Guard Cabins, Portable Toilets & Bathrooms, Portable Building, etc.

Our Products

We manufacture cabins

to your choice

Portfolio

Our Client